July 25, 2025

ContextClue: Intelligent Knowledge Management Built for Engineering Teams

Author:

Senior Data Scientist

Reading time:

10 minutes

Engineering teams are drowning in data, yet starving for knowledge. Critical specifications are buried across thousands of CAD files, assembly drawings are scattered across different PLM versions, and material certifications live in disconnected ERP systems.

A single component might have its mechanical properties documented in SolidWorks, electrical specifications in AutoCAD schematics, procurement details in SAP, and maintenance history trapped in legacy CMMS databases.

The fundamental problem is that these systems don’t talk to each other. When your CAD system shows a bearing specification, it has no connection to the ERP data showing that bearing’s supplier performance history, delivery delays, or cost trends.

When maintenance reports a failure, there’s no automatic link back to the original design decisions that led to that component choice. Critical relationships between design intent, manufacturing constraints, procurement realities, and operational performance remain invisible.

Engineers waste hours reconstructing knowledge that already exists somewhere in your ecosystem – hunting through revision histories to understand why a design decision was made, manually cross-referencing part numbers between systems, or rebuilding BOMs because the original logic is buried in email threads and meeting notes.

Projects get delayed by weeks while teams rediscover their own engineering decisions. Critical failures happen because maintenance teams can’t access design rationale. Innovation stalls because engineers spend 40% of their time searching instead of creating.

Read more: From Data Chaos to Clarity: How Knowledge Graphs Reshape Enterprise Information Retrieval

Why Generic AI Tools Can’t Solve Engineering Problems

While generic AI tools like ChatGPT, Claude, or Microsoft Copilot promise universal solutions, they fundamentally can’t understand engineering complexity. These tools are trained on general internet content and they can write marketing copy or summarize articles, but they lack the specialized intelligence that engineering work demands.

They can’t interpret the relationships in your CAD assemblies or understand that changing a bearing affects downstream shaft alignment. They don’t know that “Class 150” in piping has specific pressure ratings and flange requirements, or that “Material: AISI 316L” carries specific implications for corrosion resistance, welding procedures, and heat treatment requirements.

Most critically, they can’t connect design decisions in CAD with manufacturing constraints in ERP, track engineering changes across revision control systems, or understand the cascading effects of modifications across interconnected systems.

Engineering requires AI that understands spatial and relational thinking – recognizing that components exist in assemblies, assemblies form systems, and systems have interdependencies. It needs domain-specific reasoning that connects material properties to design decisions, manufacturing processes to geometric constraints, and maintenance accessibility to component placement.

Most importantly, it must grasp that engineering is iterative: designs evolve, decisions have rationale, and changes create cascading effects that must be tracked and managed across multiple domains.

Here is where ContextClue steps in.

ContextClue Origins: From Consulting Insights to Product Innovation

ContextClue emerged from years of hands-on consulting work with manufacturing, automotive, and aviation companies at Addepto.

As AI consultants working directly with engineering teams, we witnessed the same frustrations repeatedly: engineers spending hours hunting for specifications that existed somewhere in their systems, critical design knowledge trapped in retiring experts’ heads, and innovative projects stalled by information silos.

Through numerous implementations across different industries, we recognized the patterns: a German automotive supplier struggled with the same CAD-to-ERP disconnection as an American aerospace manufacturer, and Polish industrial equipment companies faced similar PLM fragmentation challenges as Italian automation firms.

Yet despite these industry-wide similarities, every single company had unique workflows, proprietary systems, and specific operational requirements that demanded tailored solutions.

This dual reality – universal problems with unique contexts – taught us a crucial lesson: there are no silver bullets in engineering knowledge management.

No one-size-fits-all solution can address the complexity of real industrial environments. Every company has evolved its own engineering processes, adopted different technology stacks, and developed distinct operational cultures.

ContextClue represents our response to this challenge. Rather than creating another rigid platform that forces companies to adapt to predefined workflows, we built a flexible framework that combines established best practices with the customization capabilities that real engineering environments demand.

What is ContextClue and How Does It Works

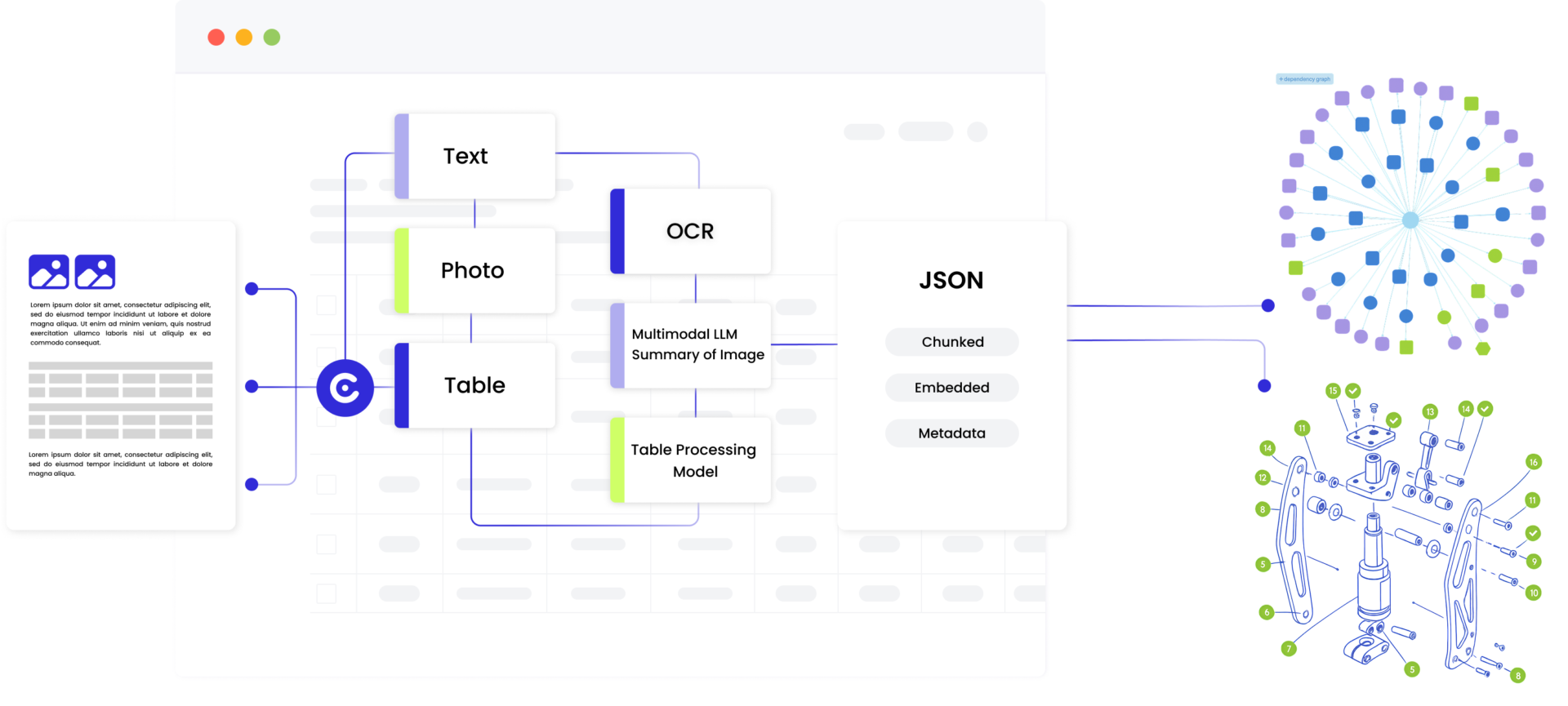

ContextClue is purpose-built for the unique challenges of engineering knowledge management. We transform your scattered technical data – CAD files, ERP systems, planning exports, and documentation – into intelligent, queryable knowledge graphs that understand engineering relationships, not just keywords.

How ContextClue Actually Works: A Real Engineering Workflow

The problem: Your maintenance team reports repeated bearing failures in Pump P-401. The replacement bearings are expensive, lead times are long, and each failure costs $50K in downtime. Your team needs to understand: Why is this happening? Are there similar pumps with the same issue? What was the original design rationale?

Traditional approach: Maintenance technician emails engineering. Engineer searches CAD system for P-401 drawings, checks ERP for bearing specifications, hunts through emails for design rationale, manually cross-references similar pumps across the plant. Total time: 8-12 hours across multiple people.

ContextClue workflow:

Ingest engine

ContextClue has already ingested and connected your CAD drawings, ERP data, maintenance records, and design documentation. It understands that Pump P-401 is a centrifugal pump, Model XYZ, with specific bearing types, operating conditions, and maintenance history.

Retrieve engine

Maintenance technician queries: “Show me all pumps similar to P-401 with bearing problems.” ContextClue’s knowledge graph instantly connects:

- 12 similar pumps across three buildings

- Common bearing specifications and suppliers

- Operating conditions and maintenance patterns

- Original design rationale from engineering notes

- Related engineering change orders

Generate engine

- ContextClue automatically creates:

- Failure analysis report connecting design, operations, and maintenance data

- Recommended preventive maintenance schedule based on similar equipment

- Procurement report for optimized bearing specifications

- Engineering change documentation for design improvements

Result: 15-minute query replaces 12 hours of manual work. Engineering insights that would normally take weeks of investigation are available instantly. Most importantly, the knowledge is preserved and accessible for future similar issues.

The Strategic Engineering Advantage: LLM Model Flexibility

Unlike platforms locked into single AI models, ContextClue’s architecture supports all standard LLM models – giving you the strategic advantage of choosing the perfect AI engine for your specific engineering workflows.

Why Synthetic Benchmarks Don’t Matter for Engineering AI

Selecting the right AI model for engineering workflows isn’t about synthetic benchmark scores like MMLU or HumanEval. These academic tests don’t reflect real engineering challenges. What matters is how the AI performs on your specific engineering data, with your terminology, in your operational context.

The reality of engineering AI selection is more about gut feeling and empirical testing. Does the AI understand your industry’s technical language? Can it maintain context across complex, multi-step engineering problems? How does it perform when prompted with your specific engineering scenarios?

This is why the prompting strategy is crucial – the same AI model can perform dramatically differently based on how you structure queries, provide context, and frame engineering problems.

ContextClue’s flexibility allows you to experiment with different models and prompting approaches to find what works best for your specific engineering challenges.

Thus, we focus on the factors that actually make a difference.

Choosing the Right LLM for Your Engineering Needs

1. Deployment Models for Engineering Environments

Where your AI runs isn’t just a technical decision – it’s a strategic choice that impacts data security, compliance, performance, and costs. The right deployment model aligns with your organization’s risk tolerance, regulatory requirements, and operational constraints.

| Deployment Model | Best For | Key Advantages | Key Considerations |

|---|---|---|---|

| External services (Cloud APIs) | Rapid prototyping, standard documentation tasks | Quick implementation, no infrastructure management, access to trending, closed models | Data leaves your environment, ongoing API costs, and dependency on external providers |

| Cloud platform models (AWS Bedrock, Azure AI) | Organizations with existing cloud infrastructure | Better data residency control, integration with cloud services, flexible scaling | Still cloud-dependent, requires cloud expertise, and has potential vendor lock-in |

| On-premise models | Aerospace, defense, pharmaceutical with strict IP requirements | Complete data sovereignty, full control, no external dependencies | Higher technical resources required, infrastructure costs, maintenance responsibility |

2. Model Complexity for Engineering Tasks

The “bigger is better” assumption is costly in engineering applications. While larger models handle complex reasoning, they’re slower and more expensive. The key is matching model capability to task complexity – using efficient models for routine work and advanced models only when sophisticated analysis is genuinely needed.

Choosing the right model size can mean the difference between 100ms responses for parts classification versus 10-second delays that disrupt engineering workflows. Cost implications are equally significant: running a 70B parameter model for simple queries can cost 10x more than an optimized 8B model.

| Model Type | Parameters | Best Engineering Applications | Performance Characteristics | Cost Implications |

|---|---|---|---|---|

| Efficient models | 8B parameters | Component classification, material property extraction, standard work instructions | Fast response times, high throughput | Lower operational costs, suitable for high-volume tasks |

| Advanced models | 70B+ parameters | Multi-system failure analysis, comprehensive design reviews, complex optimization | Slower response times, deeper reasoning capability | Higher costs, reserve for complex analytical tasks |

3. Engineering Domain Specialization

AI models can be adapted to your engineering environment through several approaches, each offering different levels of customization and investment requirements.

Custom fine-tuning: Addepto can fine-tune models specifically for your engineering domain using your proprietary technical data. This creates AI that understands your specific processes, terminology, industry standards, and operational context.

While requiring additional investment, fine-tuning delivers the highest accuracy for domain-specific tasks.

Alternative approaches without custom fine-tuning:

- Prompt engineering: Sophisticated prompting strategies that provide context and examples within queries

- Retrieval-augmented generation (included Classic RAG, Graph RAG, and Hybrid RAG): Combines general models with your technical documentation for context

- Few-shot learning: Training models on small sets of your specific examples

- Industry-specific pre-trained models: Using models already trained on engineering domains

Flexible Engineering Integration Approach

ContextClue’s integration flexibility means you don’t have to choose between powerful AI capabilities and operational reality. Our adaptable architecture lets you start where you are, integrate with existing systems, and scale according to your specific engineering environment and organizational constraints.

- System compatibility

REST API-driven architecture enables seamless integration with major engineering platforms – Siemens PLM, PTC Windchill, Dassault SOLIDWORKS PDM, AutoCAD vault systems, SAP PLM – without disrupting existing engineering workflows. - Engineering deployment options

Cloud-based deployment offers rapid implementation with enterprise-grade security and automatic updates. On-premise installation provides maximum control for sensitive engineering environments and regulatory compliance. Hybrid models balance accessibility with data sovereignty requirements. - Engineering customization levels

Pre-built connectors for common engineering systems, custom integration support for proprietary technical environments, and configurable AI models tuned for your specific engineering domain and operational processes.

Is ContextClue Right for Your Organization?

ContextClue serves two distinct types of engineering organizations, each with different technical maturity levels and infrastructure complexity.

Understanding which path aligns with your current situation is crucial for successful implementation.

| Aspect | Comprehensive Platform | Modular Integration |

|---|---|---|

| Company Size | 50-500 engineering professionals | 200+ engineering professionals across multiple locations/divisions |

| Current Infrastructure | Basic to moderate technical systems (standard PLM, ERP, file servers) | Complex, often legacy systems with existing PLM/ERP investments |

| Current Knowledge Management State | Fragmented knowledge management, limited system integration | Robust technical infrastructure with specific knowledge bottlenecks |

| Technical Maturity Required | Moderate – has IT support but not extensive system integration experience | High – experienced with system integrations, custom workflows, API management |

| Implementation Complexity | Like SAP implementation – requires technical setup, system configuration, IT involvement (not simple SaaS-like login) | Requires significant technical sophistication, API integrations, custom configurations |

| Best For Organizations That | Are building their first integrated knowledge management system Want standardized engineering documentation processes Prefer complete solution over managing multiple vendors |

Have substantial existing PLM/ERP investments Need to maintain compliance with existing workflows Want to address specific pain points without disrupting working systems Have technical teams capable of managing selective integrations |

Ready to Transform Your Engineering Knowledge?

Whether you’re looking for comprehensive engineering transformation or targeted improvements, we’ll tailor ContextClue to your technical team’s priorities.

We’ll show you exactly how ContextClue integrates with your engineering systems, solves your specific technical challenges, and unlocks engineering productivity.

Category: